ALUMINUM CATHODES

Technology and Benefits Delivered

The Limpact Aluminum Cathode technology consists of four (4) unique offerings that when combined, produce the most electrically efficient and lowest life cycle cost cathode in the industry.

1. Limpact Explosion Bonded Head Bars

2. Limpact Proprietary Solution Line Protection System (SLPS)

3. Limpact Stripping Disc Solutions

4. Limpact Edge Strip Technology

In summary, Limpact cathodes have an initial cost that is 1.5X more than a basic cathode, however Limpact cathodes have a lifetime that is 2X to 3X the lifetime of the basic bi-met cathode. As a result, the annual cathode replacement cost is reduced by 25% – 40% saving $600,000 to $900,000 per year.

Explosion Bonded Head Bar

Limpact’s unique, value-added proprietary explosion bonded contact system outlasts and outperforms any other head bar contact system in the world.

Limpact explosion bonded head bars with a single contact have a 36+ month service life. This is in comparison to a life of 10 – 12 – 14 months obtained by zinc cell houses utilizing the competing bi-metallic contact system.

Limpact’s proprietary explosion bonding process thrusts dissimilar metals together under extreme pressure that is created by the detonation of an explosive charge. The high velocity and high impact pressure of the explosive detonation creates an atomic bond which is created between the two dissimilar metals with no measurable voltage drop across the bond.

The metallurgical bond creates a shear strength equal to the metal itself.

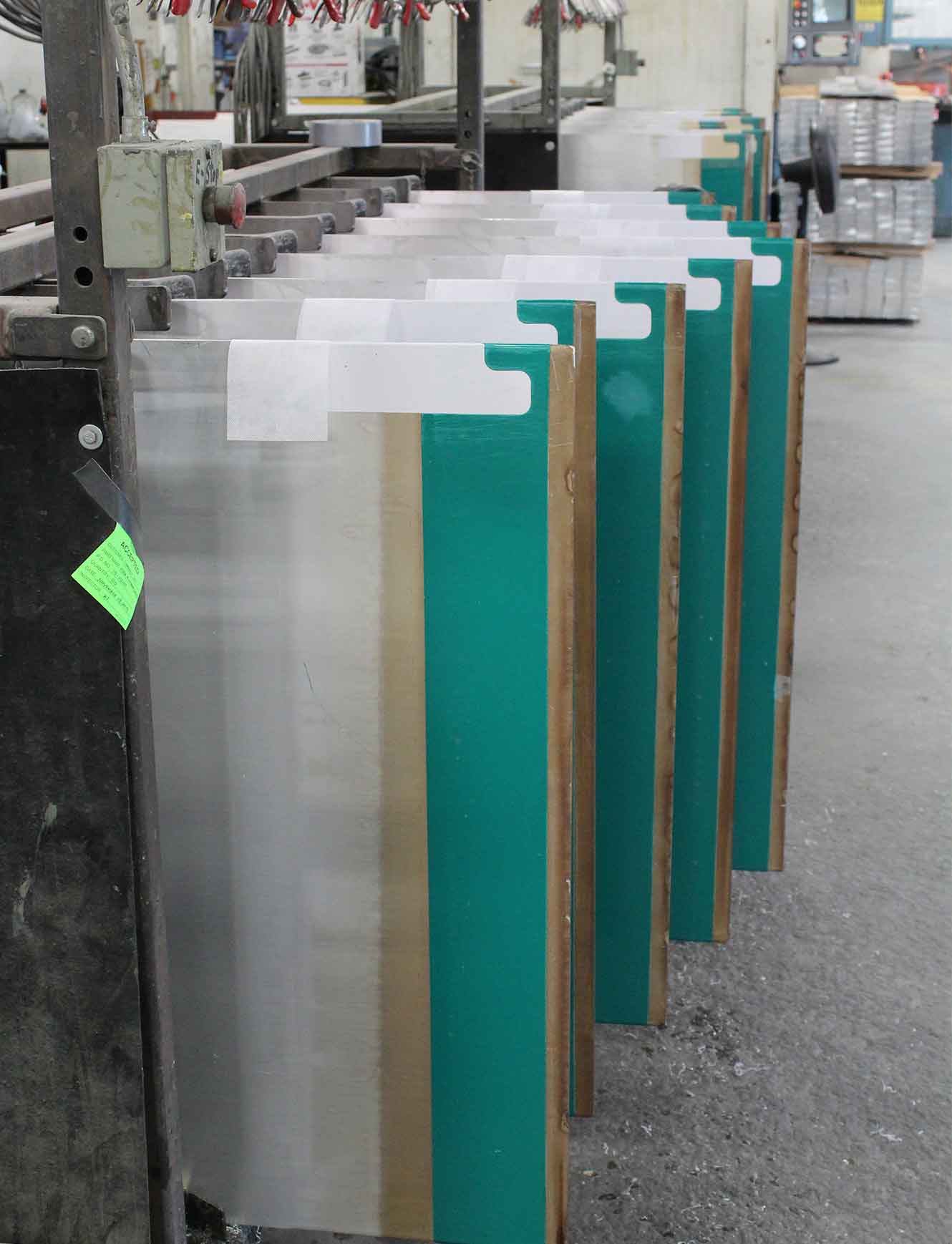

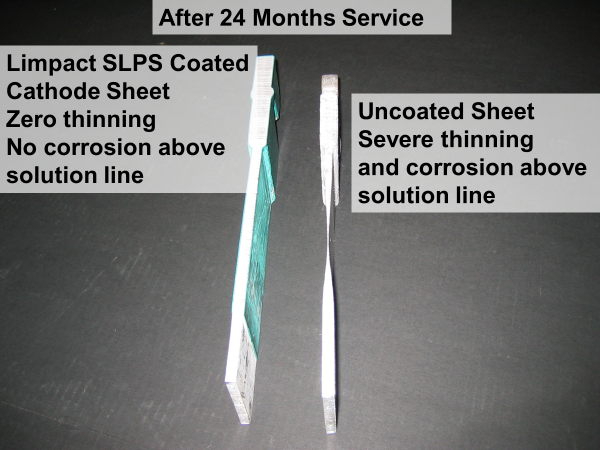

Limpact Proprietary Solution Line Protection System (SLPS)

Limpact’s unique Solution Line Protection System (SLPS) will protect the cathode sheet above the solution line against corrosion. The superior corrosion resistance of the Limpact SLPS eliminates corrosion of the Al sheet above the electrolyte level and in the area of the stripping disc. Limpact SLPS extends the sheet life to in excess of 36 months against industry standard of some 10 to 16 months.

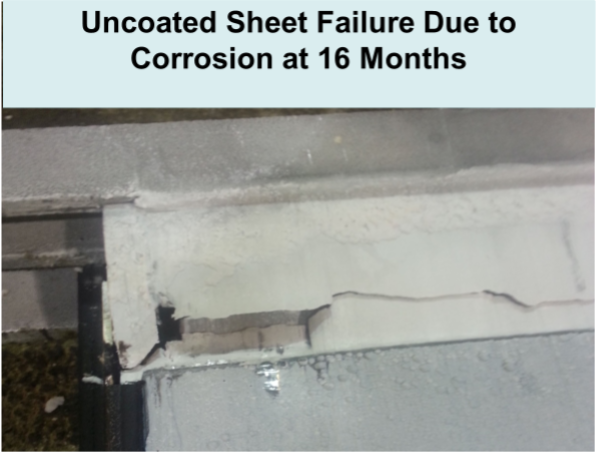

Without Limpact SLPS:

Disc fails at 12 months due to corrosion of the Al sheet in the area of the stripping disc.

Disc cannot be repaired.

With Limpact SLPS:

Corrosion in the area of the stripping disc is eliminated extending the sheet life to 36+ months.

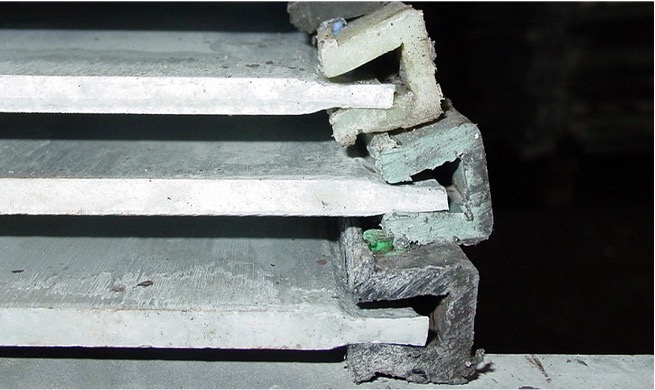

Limpact Proprietary Edge Strip Technology

Limpact’s proprietary sealant and edge strip system “locks” the edge strip to the sheet in a manner such that it can only be removed by mechanical destruction of the edge strip. In addition, the proprietary sealant eliminates the number one cause of edge strip failure, which is corrosion of the aluminum sheet under the edge strips.

Competitor “Friction Fit” Edge Strips:

Edge strips fall off after 12-14 months service due to corrosion of the Al sheet under the edge strip.

Corrosion of the aluminum sheet under the Limpact edge strip is eliminated extending the edge strip life To 36+ Months.

Limpact Lifting Hooks

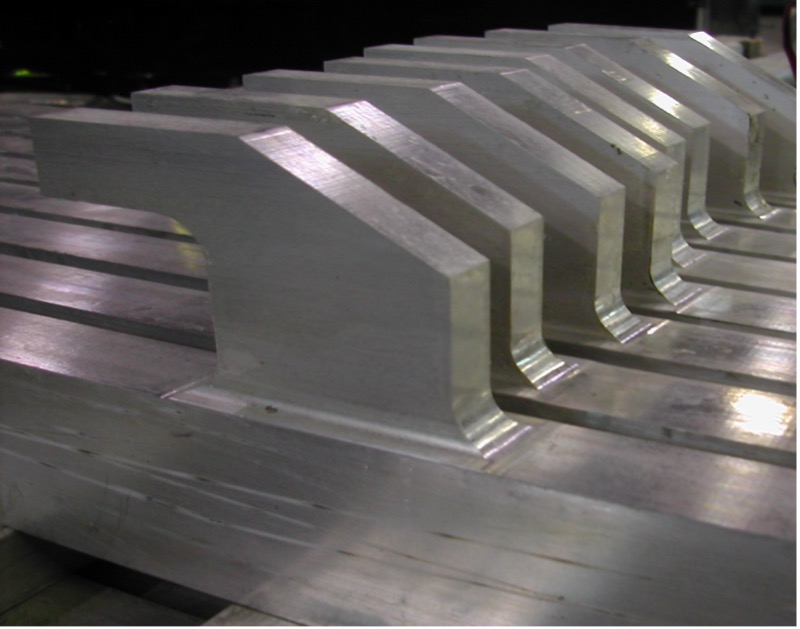

The Limpact Lifting Hooks are made from AA 6061 T6 alloy and extruded to Limpact custom shape having overall outside dimensions as specified by a customer supplied drawing.

Optionally, Limpact can supply lifting hooks which are “integral” to the head bar. A single extruded aluminium bar is procured and then the lifting hooks are machined from this bar resulting in a single extruded hanger bar with lifting hooks and no weld resulting in an improved safety environment. Integral lug head bars are utilized by many of our customers to eliminate the possibility of failure of the weld that attaches the hook to the head bar. This becomes increasingly important as the life of the head bar is extended beyond 36 – 48 months when the welds are most prone to corrosion induced failure.

Similar PRODUCTS

METALS

ferrous • electrolysis • metals

CONTACT

Telephone

Office +1-905-373-4100

Location

569 D’Arcy Street, Cobourg

Ontario Canada K9A 4B1

H0urs

AVAILABLE 24-7 – EST